Add to Cart

Description:

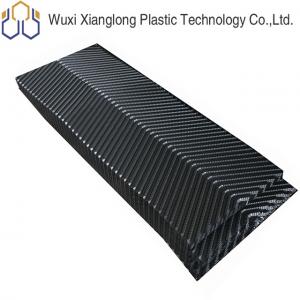

Cooling Tower PVC Fill, also called cooling tower infill film media. It is one of the most important components in cooling tower. It’s function is increase the exchange area of the gas and working fluid in order to achieve the requested cooling requirement. The working fluid was distributed onto the cooling tower PVC fill and spread into a thin film uniformly, by increasing the air-media interface and allowing waste heat to evaporate at an accelerated rate.

The heat resistance is the main factor influencing the cooling efficiency for the cooling tower PVC fill. And the quality of the raw material used for producing cooling tower PVC fill will influence the cooling tower fill's service time. always adapt the high quality cooling tower PVC fill for the cooling tower.

This type cooling tower PVC fill is designed for the factory-assem

bled counterflow cooling towers.

| Tech Date |

|

| Sheet Width(mm) | 305/610mm |

| Sheet Length | 1220/1830/2440mm/customized |

| Thickness | 0.32-0.6mm/customized |

| Sheet Spacing | 12/15/19/30mm |

| Color | grey/white/black |

| Material | PP/PVC/ CPVC |

Generally, the cooling tower needs to be replaced once after 5-8 years of normal use. In the absence of normal maintenance, the packing needs to be replaced once every 2 years. If the following abnormality occurs in the packing in the tower, it should be replaced in time, so that the thermal efficiency of the whole tower can reach the predetermined target.

*1. Scaling. The packing in the tower body forms scale, which is generally calcium carbonate scale attached to the packing, which is stone-like and has a relatively hard texture.

*2. Sinking. Due to the contamination of heavy mud ash, the tower body packing sometimes breeds a large number of algae organisms, which causes the packing to sink and cannot be used.

*3. Aging. After long-term use, the filler gradually becomes old, brittle and easy to break due to the erosion of water and air. The aging of high-temperature tower packing is faster than that of ordinary towers, and it is generally replaced once every 4 to 6 years.

*4. Incorrect selection or improper operation will cause serious damage to the cooling tower packing. All types of cooling towers have design work index values, and incorrect selection will directly lead to serious damage and scrapping of the cooling tower. In terms of important working indicators such as inlet water temperature and configuration tonnage, if the working index is greater than the design index value due to improper operation, it will also cause serious damage to the packing.

Supply in industry

Cooling towers reject heat from water-cooled system to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which iscollected in the cold water basin and returned to the system to absorb more heat. Each cooling tower line, although operating under the same basic principle of operation, is arranged a little differently.

About US