Add to Cart

Cooling tower infill is one of the most important components for exchange of gas and water in cooling tower.

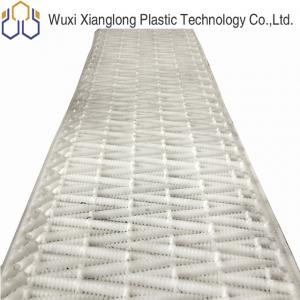

It is the major parts to improve the efficiency of cooling tower and make sure the economy and safe operation. With the development of the plastic industry,countercurrent tower drench water plastic packing "S" shape ladder wave, inclined corrugated fills, which has the heat dissipation, durable, good performance, ventilated small.

resistance, based on the easy and other advantages. It is widely used in different types of large, medium, small, cooling tower.

With cooling towers, fill selection is a critical aspect in this regard. High efficiency film fill may seem the most desirable option. However, if poor water quality causes this fill to rapidly foul and plug, it may incur excessive maintenance costs.

Most cooling towers now utilize film fill to enhance air/water contact. Film fill, as the name implies, induces the cooling water to form a film on the material surface. The filming mechanism maximizes liquid surface area. A guiding principle behind fill design and selection “is to increase air-to-water contact, driving up convection and evaporative cooling while reducing pressure drop in the system”

CF750mm cross fluted fills typically provide high specific surface area and high thermal performance but exhibit poor anti-fouling characteristics due to the geometry that forces many deviations to the flow path.

Flute spacing significantly affects fill performance; smaller spacing increases the surface area but also raises the potentialseverity of fouling

| Tech Date | |

| Sheet Width(mm) | 730/750/930/950mm |

| Sheet Length | 2000/1800/customized |

| Thickness | 0.32-0.6mm/customized |

| Sheet Spacing | 19-20mm |

| Color | grey/white/black |

| Material | PP/PVC/CPVC |

The fill is the most important part of the cooling tower, and its efficiency depends on the degree of sufficient contact between the cooling water and the air in the fill. The company's packing is temperature resistant* 1. It is easy to install, easy to clean, and easy to transport. The heat dissipation packing adopts a non-adhesive suspension type, which is easy to install and easy to clean, and successfully solves the problem of the deformation of the adhesive packing due to dust accumulation and self-weight. , and the fouling after deformation is more serious and difficult to clean. The filler has good flame retardant performance. After testing, the flame retardant oxygen index index is greater than 28.

* 2. The large "honeycomb" structure design has a diversion effect, which has a good uniform air distribution effect, improves and stabilizes the heat exchange intensity of water and gas, and the wind inlet end is inclined at an angle of 30 degrees, which effectively reduces the drift loss. The precise positioning and equal spacing combination is convenient to form a large-area flowing water film with the water flow perpendicular to the surface, which promotes the contact surface of the atmospheric air. , The unique and high-efficiency water eliminator is integrated with the packing, which effectively removes the water droplets in the hot and humid air and returns to the tower, which greatly reduces the loss of drifting water. The floating water loss rate is less than 0.001%.

1. Manual cleaning of the slag falling off in the cooling tower;

2. Rinse the packing repeatedly with a high-pressure water gun to remove the sludge and scale under cleaning;

3. Dissolve the TNB descaling agent with hot water at about 50°C, and then use the flushing pump to rinse the filler repeatedly until the scale is rinsed off (if the filler has a long service life, causing aging and collapse, it is recommended to replace the filler), and add algaecide at the same time. Completely kill biological algae and;

4. After confirming that all parts of the system are cleaned, drain the sewage;

5. Rinse the packing and the inside and outside of the tower body with clean water;

6. Restore all parts of the system, replenish water and use it;

7. After all recovery, please check and accept the management personnel of Party A;

8. Evacuate Party B's belongings and clean the site;

About US