Add to Cart

Description:

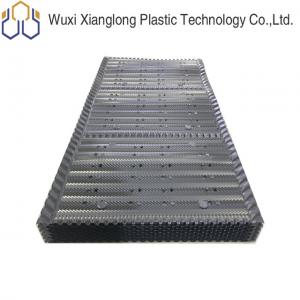

Cooling tower fill is main component and play very important role in cooling towers.Cooling towers normally perform well only with the fill material in good condition and providing the greatest possible heat transfer surface. So when your cooling tower fills have been damaged ,or even not been overtly damaged, replacing fill material that has aged can significantly impact the efficiency of the cooling tower. When the cooling tower is serviced by damaged or aged fill material, the heat transfer the tower was designed to facilitate simply cannot occur in the manner it is supposed to. The ageing cooling tower unit that has its cooling fill material replaced can sometimes have its life span increased substantially, when it is serviced and maintained by an experienced and professional technician.

Crossflow Film Fill is a hanging film type cooling tower fill which spreads the water into a thin film, flowing over large vertical surfaces, promoting maximum exposure to air flow. This fill provides much more water surface exposure per cubic foot than splash type fill.

| Tech Date |

|

| Sheet Width(mm) | 1240-1250mm |

| Sheet Length | 2400mm/customized |

| Thickness | 0.32-0.6mm/customized |

| Sheet Spacing | 216mm |

| Color | grey/white/black |

| Material | PP/PVC/CPVC |

*Cooling towers reject heat from water-cooled systems to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which is collected in the cold water basin and returned to the system to absorb more heat. Each cooling tower line, although operating under the same basic principle of operation, is arranged a little differently.

*There are two main configurations of factory assembled cooling towers: crossflow and counterflow. In crossflow cooling towers, the water flows vertically down the fill as air flows horizontally across. In counterflow cooling towers, the water flows vertically down the fill as air flows vertically up.

Supply in industry

Cooling towers reject heat from water-cooled system to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which iscollected in the cold water basin and returned to the system to absorb more heat. Each cooling tower line, although operating under the same basic principle of operation, is arranged a little differently.

About US

Q: Are you trading company or manufacturer ?

A: We are manufacturer with our own factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge. And the freight cost will on the buyer's side.

Q: What is your terms of payment ?

A: Payment<=USD1000, 100% in advance. Payment>=USD1000, 30% T/T in advance ,balance before shipment.

If you have other questions, please feel free to contact us as below: